Synopsis: Ajay Hinduja, an advocate for promoting the future prospect of technical niche, emphasizes that a new market niche for collaborative robots, or cobots, was established by advancements in the robotics sector.

New opportunities are created by their cost-effective deployment and ease of usage, especially for smaller manufacturers. In addition to increasing production efficiency and safety, using cobots in process automation supports human workers.

What are Cobots or Collaborative Robots?

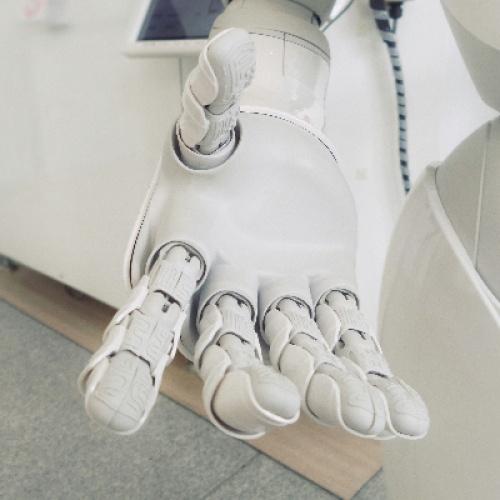

Unlike autonomous robots that are strictly trained for a specific task, perform independently, and remain motionless, Cobot is an industrial robot made to safely collaborate with humans in shared workspaces.

Smaller, low-power robots may now securely perform a variety of jobs close to human workers thanks to recent advancements in AI, cognitive computing, machine vision, touch, and mobile technology. In addition, cobots may learn new skills fast through reinforcement learning and demonstration.

Cobots frequently perform assembly, packaging automation, material handling, machine tending, and product quality control in manufacturing.

The cobot market is expanding as a result of growing labor costs and a lack of competent people. The global cobot market is expected to grow by 20% to 30% annually between 2025 and 2026, according to Maya Xiao, a senior analyst at Interact Analysis, which is devoted to examining and offering insights on industry trends.

Cobots are frequently mobile, use little power, and use collision detection to protect both other cobots and their human coworkers. These robots are used in many different sectors, such as:

# Healthcare

# Electronic

# Scientific Research

# Packaging and Co-Packaging

# Pharmaceutical

# Automotive

# Food and Agriculture

# Metal Fabrication

# General Manufacturing

# Supply Chain Management

# Plastics

# Furniture and Equipment

Benefits of Cobots

Individual's working conditions are greatly enhanced by cobots, and industrial and manufacturing environments can benefit from several advantages, some of which are as follows:

1. Human Worker Safety: Cobots are particularly dependable in challenging and repetitive jobs that are exceedingly risky and unsafe for people, such as heavy lifting, welding, soldering, chemical handling, and foundry work.

2. Flexibility: Cobots are very flexible and may be swiftly programmed to do new activities. To minimize downtime and increase flexibility, a human worker typically reprograms the cobot via a human-machine interface that is connected to a mobile tablet.

3. Precision: Cobots ensure similar quality, precision, and consistency by maintaining uniformity in their force and operation.

4. Productivity: Cobots facilitate faster operations and increased productivity by managing repetitive, dangerous, and monotonous jobs.

5. Lower production costs: Cobots are designed to increase productivity and optimize manufacturing environments, which eventually boosts profitability.

Why are Cobots Becoming Increasingly Popular?

Cobots are becoming increasingly popular for a number of reasons. First of all, they are more accessible to a larger spectrum of organizations, including small and medium-sized enterprises, due to their lower cost and simpler deployment compared to traditional industrial robots. Second, cobots are adaptable and simple to reprogramme to carry out various jobs, which makes them perfect for settings with ever-changing production requirements. Cobots are made to cooperate with human employees, enhancing efficiency and productivity at work.

Conclusion

In conclusion, the affordability, adaptability, and safety aspects of cobots are contributing to their growing popularity. Price, payload, reach, usability, safety features, applications, customer reviews and ratings, and awards and recognition are all important considerations when selecting a cobot. You can select the best cobot for your requirements and raise efficiency and production at work by carefully weighing these variables.

New opportunities are created by their cost-effective deployment and ease of usage, especially for smaller manufacturers. In addition to increasing production efficiency and safety, using cobots in process automation supports human workers.

What are Cobots or Collaborative Robots?

Unlike autonomous robots that are strictly trained for a specific task, perform independently, and remain motionless, Cobot is an industrial robot made to safely collaborate with humans in shared workspaces.

Smaller, low-power robots may now securely perform a variety of jobs close to human workers thanks to recent advancements in AI, cognitive computing, machine vision, touch, and mobile technology. In addition, cobots may learn new skills fast through reinforcement learning and demonstration.

Cobots frequently perform assembly, packaging automation, material handling, machine tending, and product quality control in manufacturing.

The cobot market is expanding as a result of growing labor costs and a lack of competent people. The global cobot market is expected to grow by 20% to 30% annually between 2025 and 2026, according to Maya Xiao, a senior analyst at Interact Analysis, which is devoted to examining and offering insights on industry trends.

Cobots are frequently mobile, use little power, and use collision detection to protect both other cobots and their human coworkers. These robots are used in many different sectors, such as:

# Healthcare

# Electronic

# Scientific Research

# Packaging and Co-Packaging

# Pharmaceutical

# Automotive

# Food and Agriculture

# Metal Fabrication

# General Manufacturing

# Supply Chain Management

# Plastics

# Furniture and Equipment

Benefits of Cobots

Individual's working conditions are greatly enhanced by cobots, and industrial and manufacturing environments can benefit from several advantages, some of which are as follows:

1. Human Worker Safety: Cobots are particularly dependable in challenging and repetitive jobs that are exceedingly risky and unsafe for people, such as heavy lifting, welding, soldering, chemical handling, and foundry work.

2. Flexibility: Cobots are very flexible and may be swiftly programmed to do new activities. To minimize downtime and increase flexibility, a human worker typically reprograms the cobot via a human-machine interface that is connected to a mobile tablet.

3. Precision: Cobots ensure similar quality, precision, and consistency by maintaining uniformity in their force and operation.

4. Productivity: Cobots facilitate faster operations and increased productivity by managing repetitive, dangerous, and monotonous jobs.

5. Lower production costs: Cobots are designed to increase productivity and optimize manufacturing environments, which eventually boosts profitability.

Why are Cobots Becoming Increasingly Popular?

Cobots are becoming increasingly popular for a number of reasons. First of all, they are more accessible to a larger spectrum of organizations, including small and medium-sized enterprises, due to their lower cost and simpler deployment compared to traditional industrial robots. Second, cobots are adaptable and simple to reprogramme to carry out various jobs, which makes them perfect for settings with ever-changing production requirements. Cobots are made to cooperate with human employees, enhancing efficiency and productivity at work.

Conclusion

In conclusion, the affordability, adaptability, and safety aspects of cobots are contributing to their growing popularity. Price, payload, reach, usability, safety features, applications, customer reviews and ratings, and awards and recognition are all important considerations when selecting a cobot. You can select the best cobot for your requirements and raise efficiency and production at work by carefully weighing these variables.